Automation

Let's see what I've experienced with automation (Industrial; Operational Technology; PLC;

SCADA). [Click on the titles to see each article.]

{To see all my project experiences, go to the 'Archived' page.}

(NOTE: These articles are personal records of what projects I have attempted. These are not

articles to take directions from; instead, I have left references to those articles at the

end.)

Why I Did This

In my pursuit of industrial automation knowledge, I wanted to see what open source SCADA

software was suitable for learning, practicing, and using with my previous automation setups

(PLCs). SCADA is 'Supervisory Control And Data Acquisition', and it's software that

acts to oversee multiple PLCs, DCSs, RTUs, by: giving visual representations of the plants

(Human Machine

Interface, HMI) that can also be used to send control commands, collect alarms, capture

all tag data into databases (like SQLite) and retrieve that data into a time-series chart

(historian), and creating scripts for producing new conditions and actions from combined PLC

conditions (like PLC1 can affect PLC2, or, PLC1 and PLC2 at specific conditions can together

cause a new state); this all together increases the overall power a user can have with

multiple automation systems, therefore, it is a valuable tool to learn.

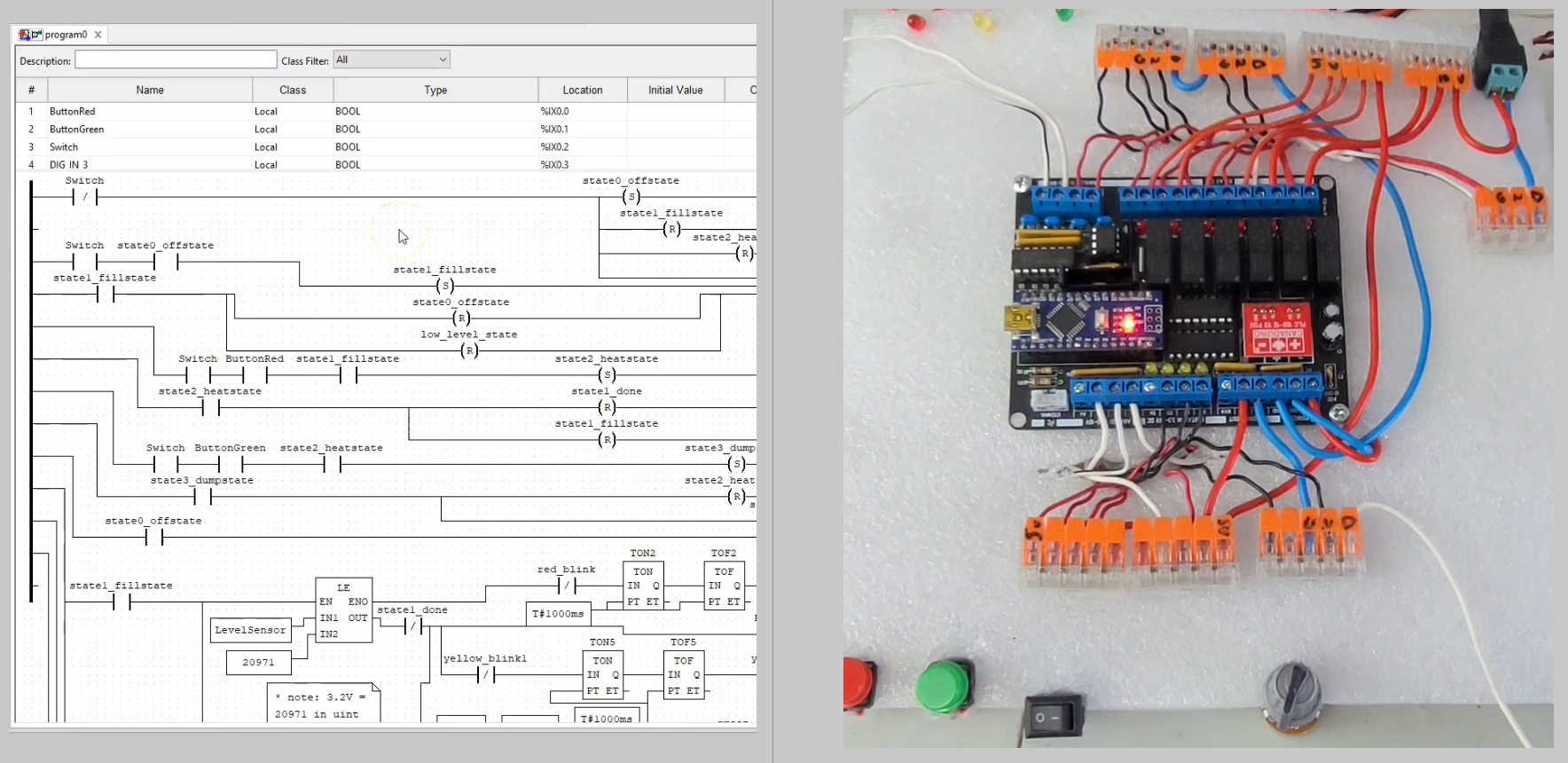

Why I Did This

While scouting online for cheap physical PLC options, I found the Canaduino PLC 100 on

Amazon.

It's a small board (about $30) that I had to solder myself and can

attach to an Arduino Nano. It contains ruggedized inputs and outputs at higher

voltages than what the Nano natively supplies, like

6 relay digital outputs with optoisolators; 4 digital inputs that can handle 3.3 - 24V; 4

analog inputs and 4 analog outputs that can both track in ranges between 0 - 10 V (very

similar to what many professional PLCs can do);

onboard LEDs for digital state notification; and 5V and 10V supply lines.

More importantly, it can be programmed with free Arduino IDE or the free OpenPLC editor and

runtime.

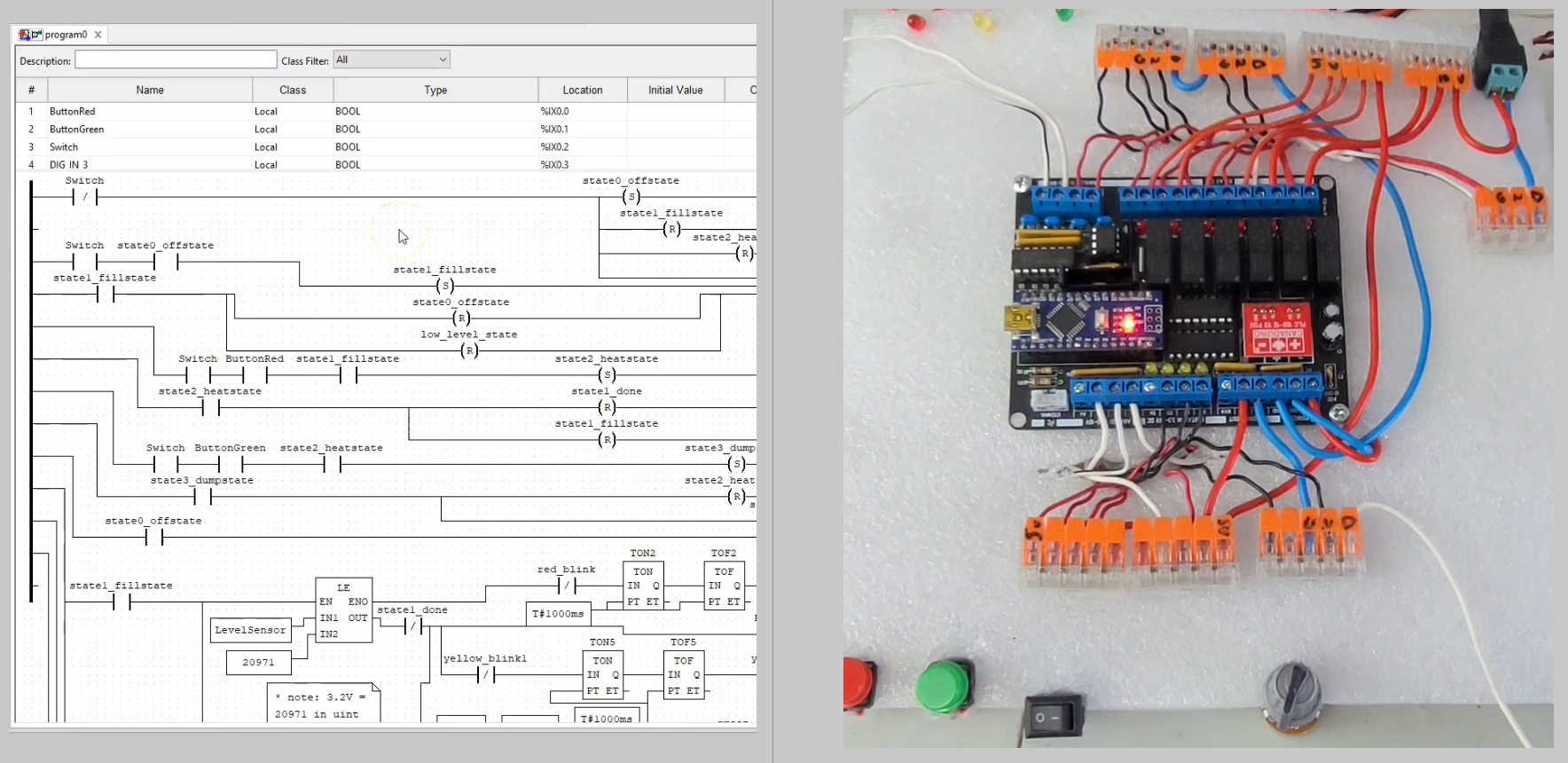

In this video, I showcase the board demonstrating its power with a makeshift 'water heater

and humidifer plant'.

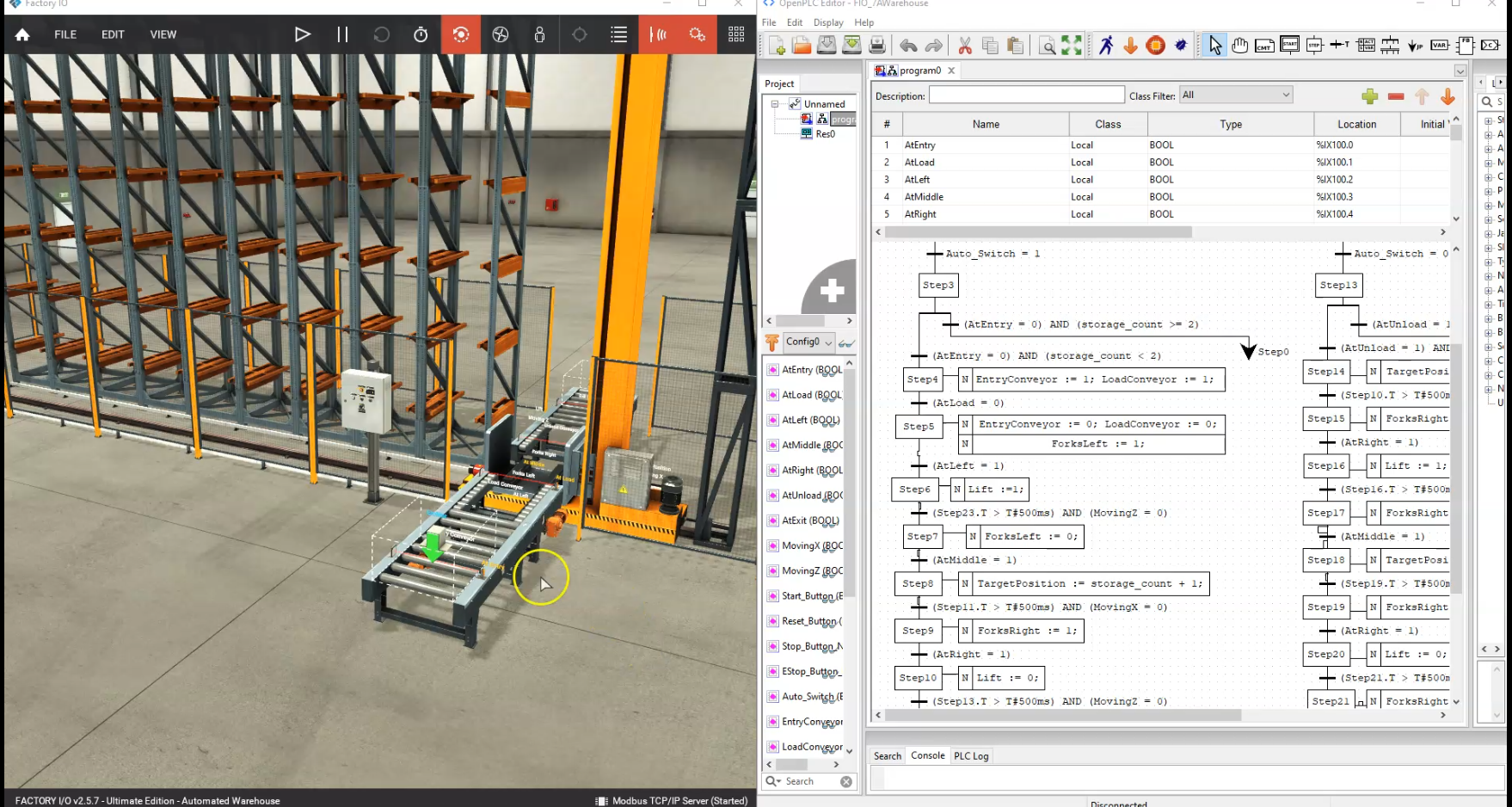

Why I Did This

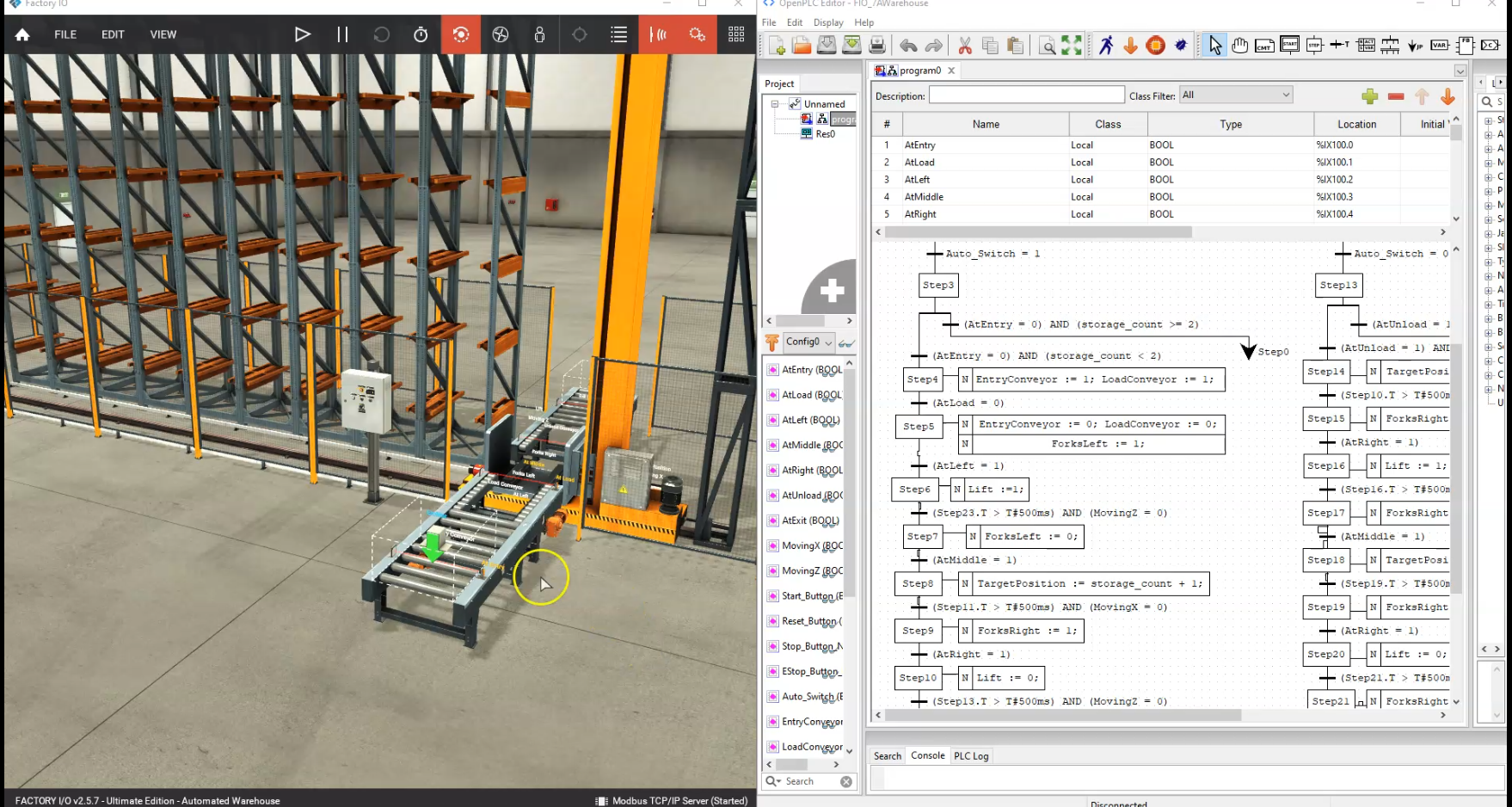

In previous articles, I've mentioned training and experiencing PLC development using OpenPLC

and FactoryIO.

In this demo, I using SFC to program FactoryIO's warehouse scene.

Why I Did This

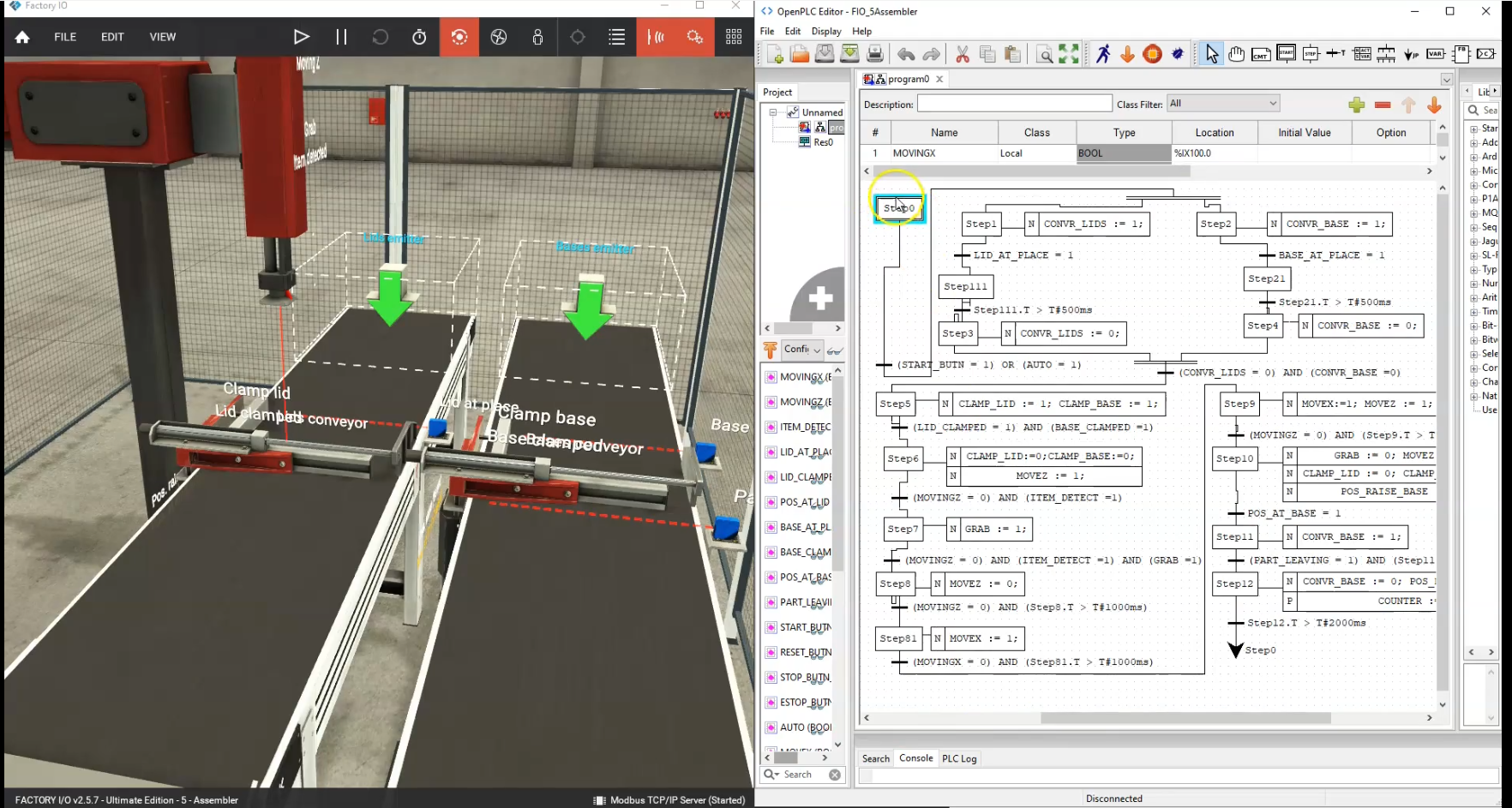

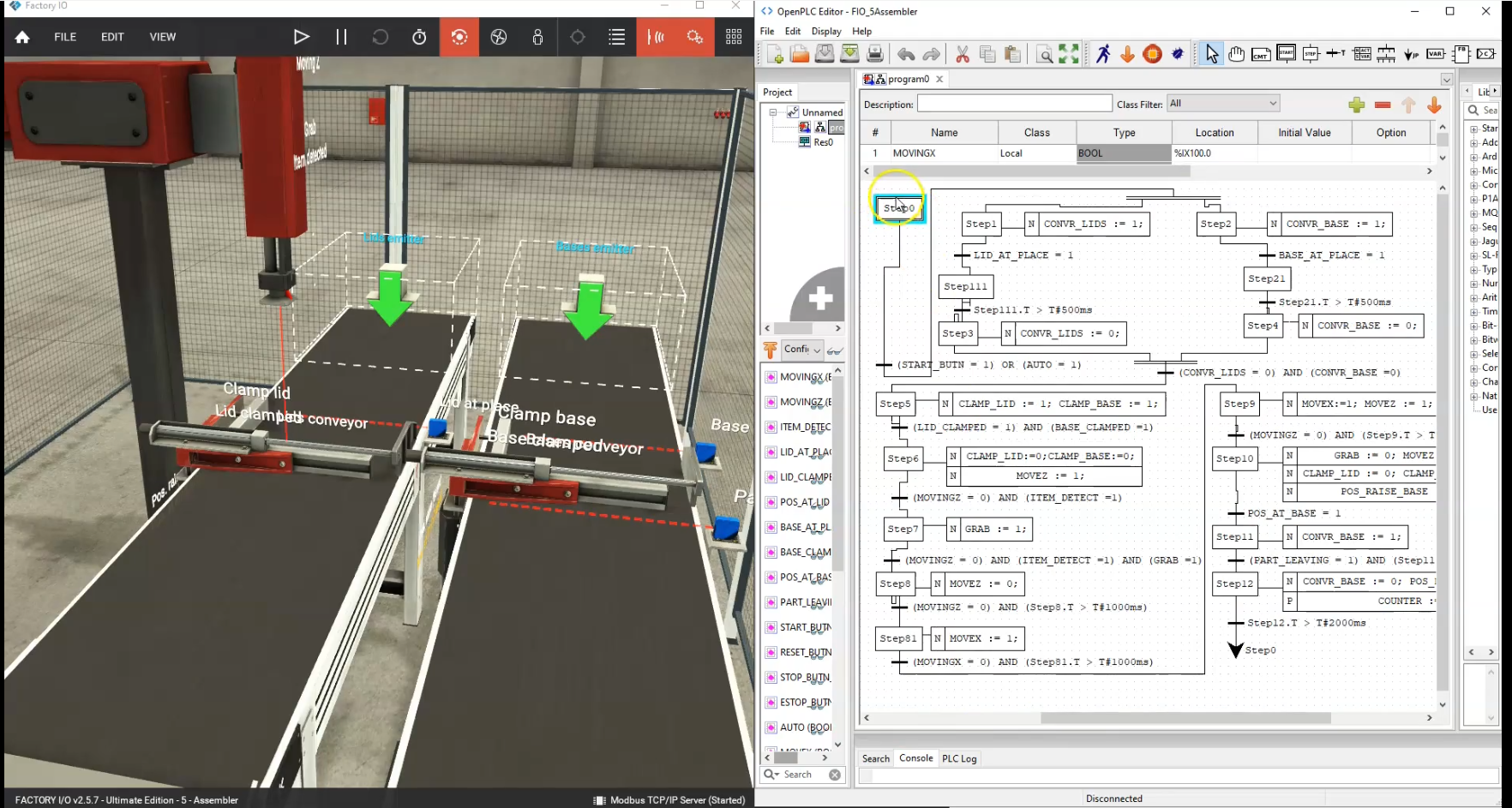

In previous articles, I've mentioned training and experiencing PLC development using OpenPLC

and FactoryIO.

In this demo, I using SFC to program FactoryIO's pick and place scene.

Why I Did This

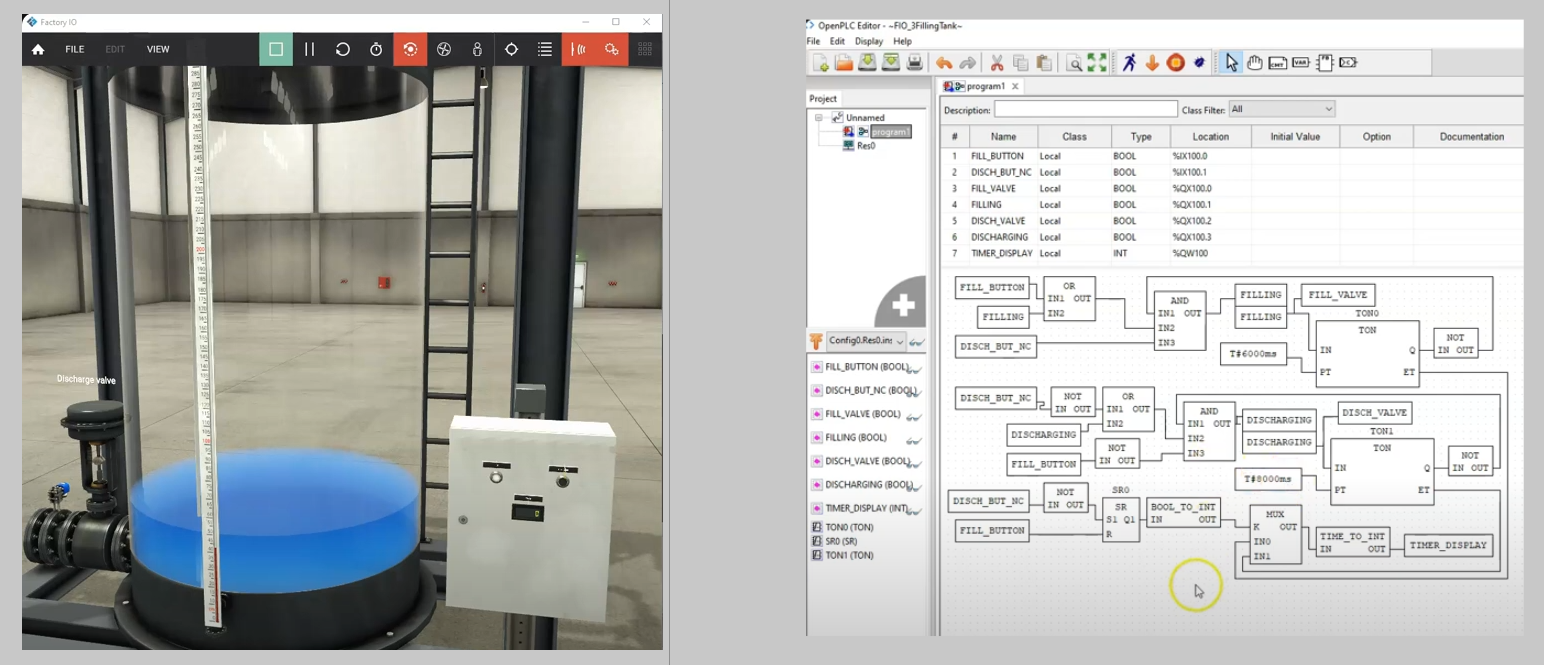

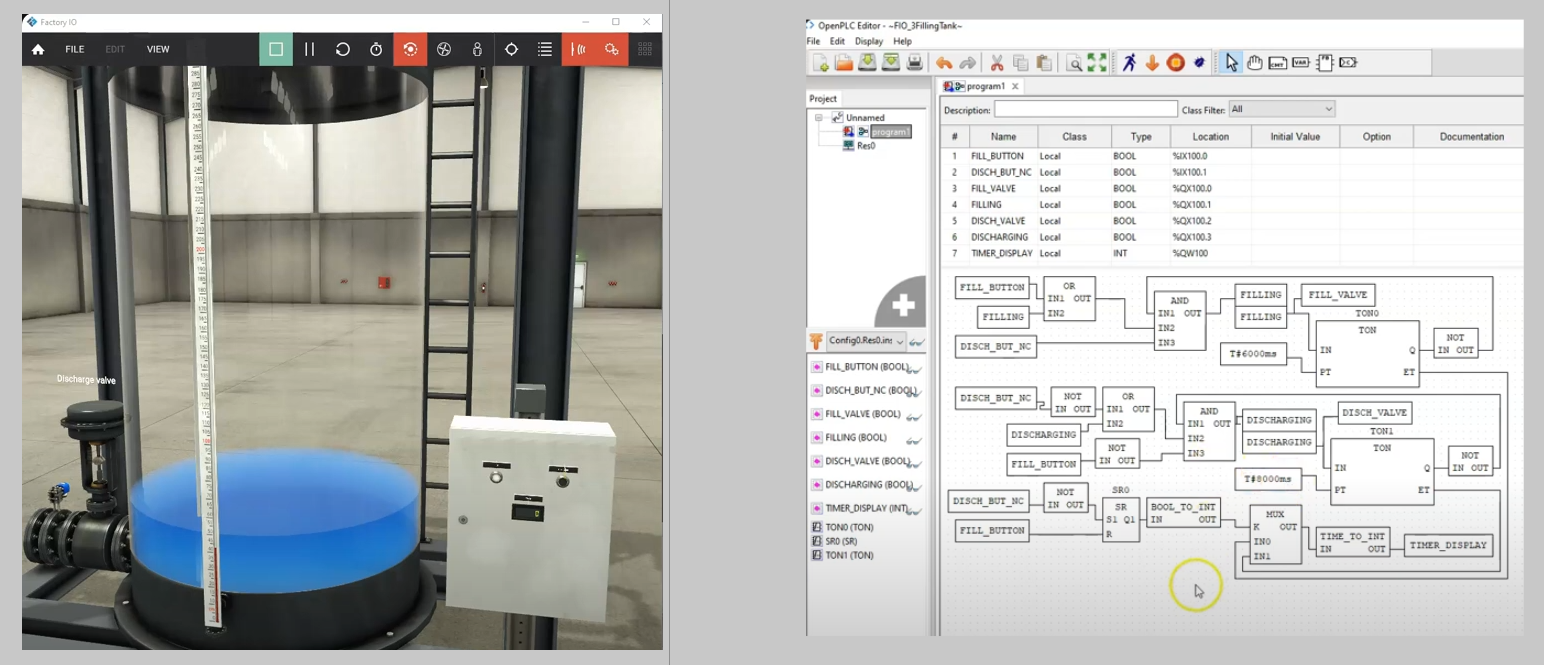

In previous articles, I've mentioned training and experiencing PLC development using OpenPLC

and FactoryIO.

In this demo, I using FBD to program FactoryIO's filling tank scene.

Why I Did This

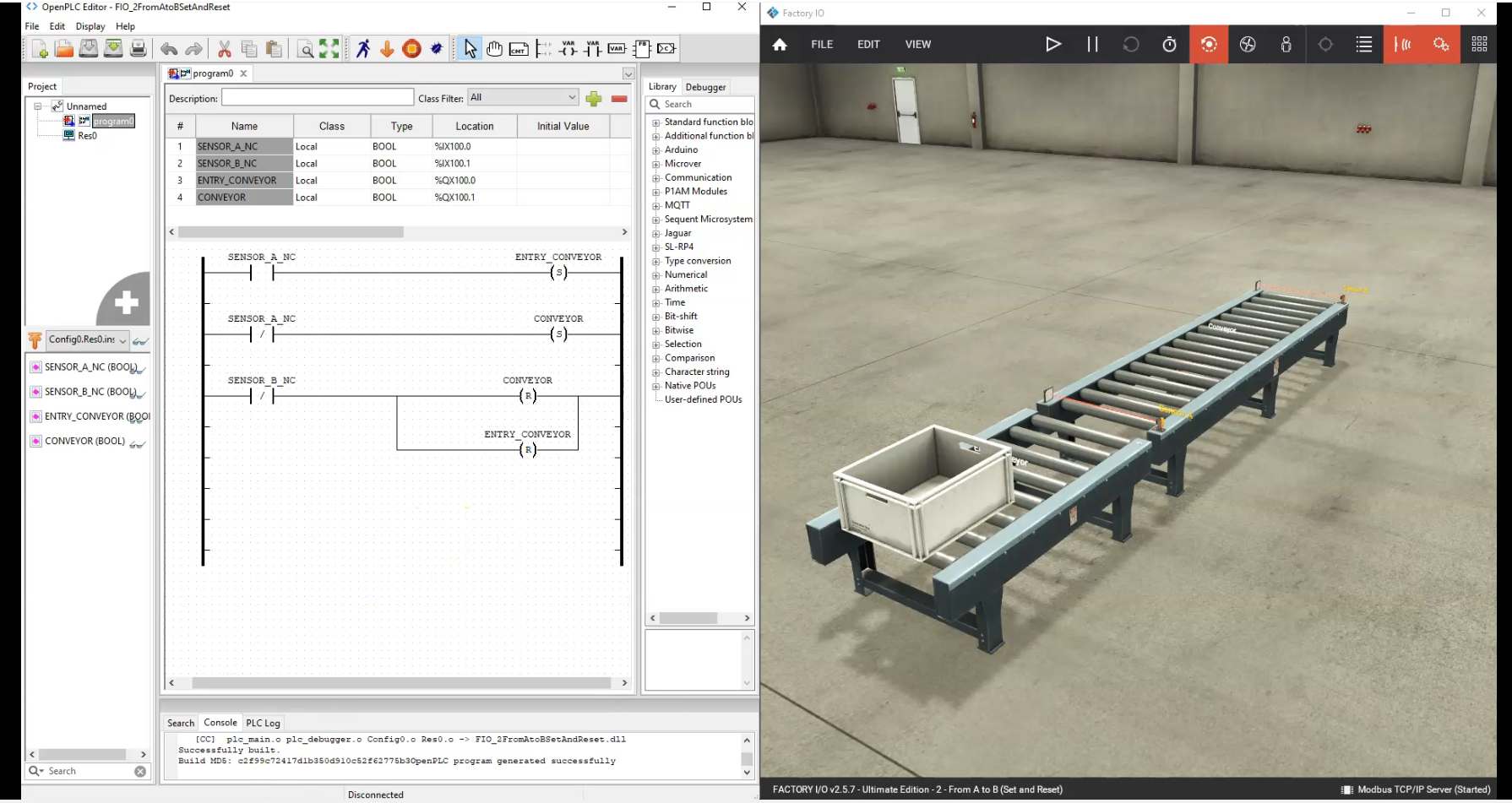

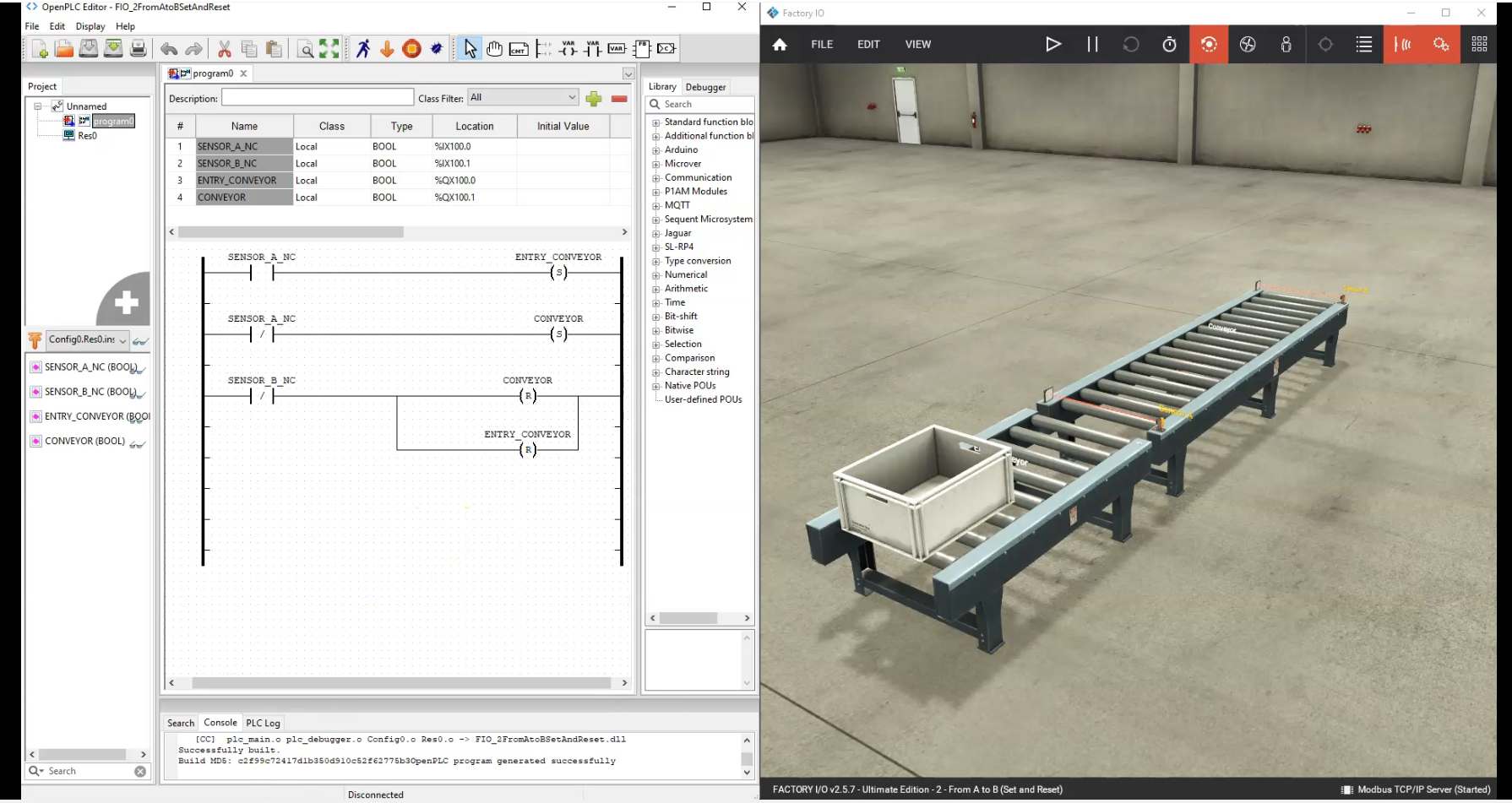

I'm trying to develop my PLC automation skills as a possible career path, and I'm currently

a

student with a student budget.

PLC programming software can be expensive, and I wanted to find a way to expand my learning

of PLC programming (and utilize test projects) without breaking the bank.

OpenPLC is an open-source PLC programming software that can run on a Raspberry Pi, Arduino,

or just your own PC, and FactoryIO is a virtual plant software that can simulate a plant

environment (which you can get a free trial for 30 days).

Together, they can be used to learn PLC programming and simulate a plant environment for

free (for 30 days, then about $20/month for FactoryIO).

This is my demo of how to get these to work together using the Modus communication protocol

as a link.

TAGS: electronics; automation; industrial; PLC; Allen Bradley MicroLogix, CompactLogix,

ControlLogix; Ladder; Function Block; Sequential Function Diagram; Structured Text

Why I Did This

One of the possible careers paths I wanted to branch into was Automation. I had previous

history with industrial operations,

so using industrial automation controls (dubbed Operational Technology) and using PLC

(programmable logic controllers) systems;

but less familiar with the programming side of it (I only 'heard' of Ladder logic and

function block programming).

NAIT offered courses in PLC programming, and I wanted to learn more about it. I took the PLC

Ladder Logic Programming and PLC Advanced Programming courses

where I learned to program in the different IEC 61131-3 languages (Ladder Logic, Function

Block Diagram, Structured Text, Sequential Function Chart,

but not Instruction List as lots of companies consider it too archaic). I also learned to

program Allen Bradley MicroLogix 1100 controllers using RSLogix 500 software; and then

CompactLogix 1769-L24ER controllers and 1756-L71 ControlLogix Logix5571

controllers using Studio 5000 Logix Designer.

We also did some short programming/training on a microsystems SCADAPack32 remote terminal

unit (RTU) when we were

learning of

different communications protocol/methods, but these were slower systems so the training was

minimally covered.

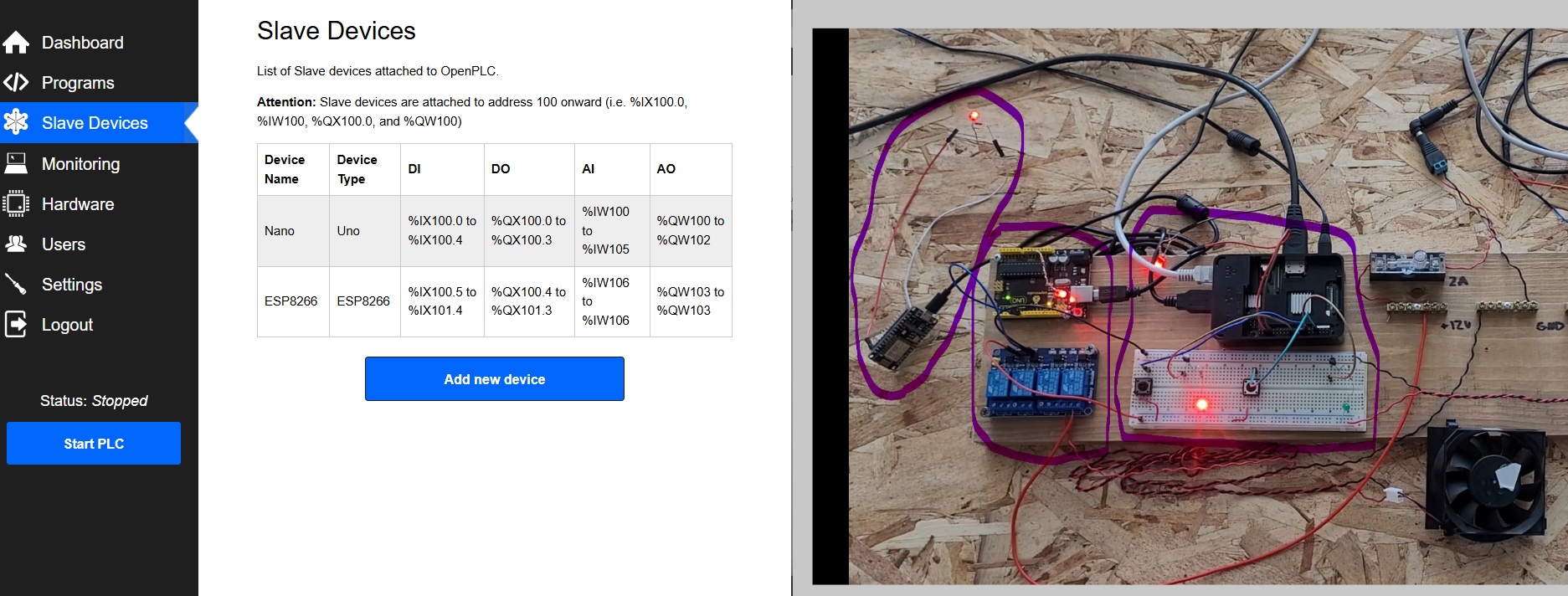

Why I Did This

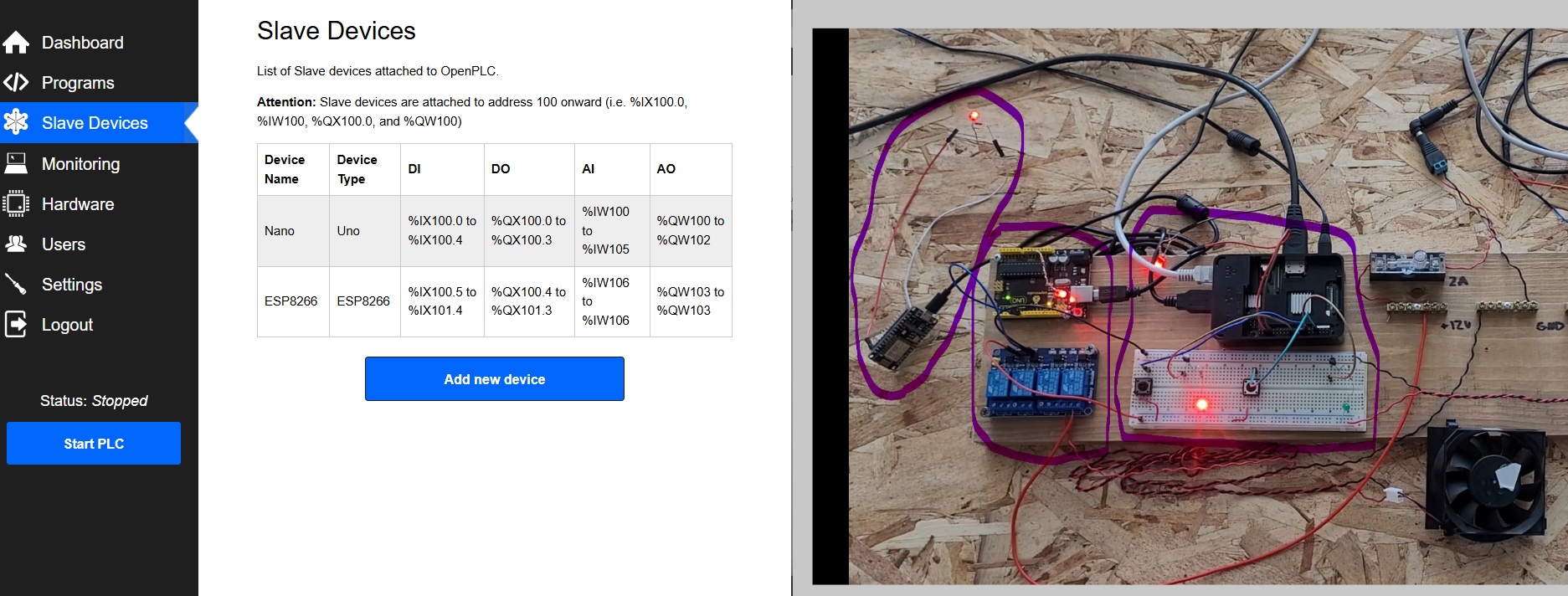

In my pursuit to experience industrial automation and PLC programming, I wanted to test the

OpenPLC runtime on my Raspberry Pi.

I wanted to see how effective this runtime was and

how effective the ability to connect to slave devices was. OpenPLC allows users to install

the runtime (the PLC cycle) on a Raspberry Pi, but also can program Arduinos and ESP

microcontrollers to act as I/O extensions (giving the ability to connect more sensors

actuators, but also wireless connectivity), all apparently with the help of Modbus

communication.